WasteCare Corporation is your source for commercial trash compactors, balers, waste equipment, recycling equipment, industrial shredders and grinders, and other waste related products and services.

BOTTLE CAN CRUSHER - MULTI-CHAMBER

This machine has been discontinued

For Baler Use and Reference Guide click here

For Baler Application Guide click here

MULTI-CHAMBER BOTTLE CAN CRUSHER - BCC-1600

Request Info on Multiple Products - (Secure Area)

The Bottle Can Crusher can operate on Single Phase Power and yet it can crush PET bottles

with the caps on! The standard dual chamber and the ability to add more chambers means that sorting and crushing can take place with ease. The very dense, yet easy to handle bales of crushed PET and aluminum cans can easily be stacked. The cans do not require any tying and the PET bottles require just two bands.

PET Bottles are processed by first perforating the bottles and then crushing them so that this two step process is performed quickly and efficiently. When the machine is set to the 'Can' mode, no perforation step takes place.

When set to Plastic mode the spikes system is

activated. The base machine is a dual chamber and additional chambers can be

added.

This Bottle Can Crusher is top loading which means it is very easy to use. The Moveable Head (or Compaction Mechanism) slides back and forth effortlessly so that bottle and can deposits can easily be made in their respective chamber.

FEATURES

- Standard double chamber with ability to easily add more chambers

- Sort and Crush in 1 step

- A unique spiking or perforation system for puncturing the PET bottles.

- Bales are small and easy to handle.

- Bales are Dense and easy to stack

- Fed from the top with bulk feed capabilities

- Adjustable Bale Height

- No Preconditioning of material is required

- Push Button controls allows users to easily change between Bottles and Cans

- Makes Stackable bricks of aluminum cans that break apart easily at processing center.

- No banding is required for Can bales

- Only one banding is required on PET bales

- Bale ejection system

- Designed with health and safety standards in mind.

- Small Footprint (46" W x 26" D x 84" H)

LOTS OF USER FRIENDLY FEATURES FOR EASY BALING OF PET AND CANS

Push Button Controls Cans in one Chamber PET in another Chamber

Approximately 11,000 cans per Skid (24 Bales) Approximately 11,000 PET Bottles per Skid (24 Bales)

Multi-Chamber Bottle Can Crusher - Specifications

| Bale Size | 16" W x 16" D x 14" - 22" H |

| Bale Weights

-Aluminum Cans -Plastic Bottles |

up to 25 pounds up to 30 pounds |

Bales / Hr with 2 Chambers (Cans & PET) |

5 - 6 Bales per hour (Approx 400 - 425 Cans & PET bottles per bale) |

Bales / Hr with 3 Chambers (1 & 2 Liter Bottles) |

4 Bales per hour or approx 1,850 bottles per hr - (Approx 350 - 500 bottles per bale) |

| Ram Force | 13,200 Pounds |

| Compaction Ratios PET | Ranges from 9 to 1 to 13 to 1 |

| Compaction Ratios Cans | Approx. 6 to 1 |

| Cycle Time | 33 Seconds |

| Motor | 1.5 HP |

| Noise Level | Less than 70 db |

| Protection Class | IP 55 |

| Electrical Power | 115v 60 Hz / 230v 50 Hz, 1 PH 10A |

| Bale Ejection System | Yes |

Multi-Chamber Bottle Can Crusher Dimensions

| Loading / Charge Opening | 16" x 16" |

| Feed Height | 39" |

| Overall Height | 85" |

| Overall Width | 46" |

| Overall Depth | 27" |

| Depth with doors open | 41" |

| Chamber Dimensions | 16" W x 16" D x 31" H |

| Bale Size | 16" W x 16" D x 14" - 22" H |

| Shipping Height | 89" |

| Actual Weight | 1,050 Pounds |

| Installation and Operating Area | 15 Square Feet |

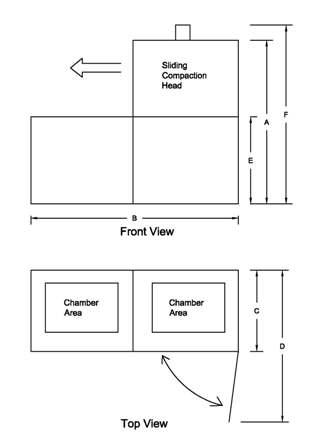

Multi-Chamber Bottle Can Crusher Diagram

A: 85" B: 46" C: 27" D: 41" E: 39" F: 89" (Transport Height)

Note: Specifications, Dimensions & other product details may vary slightly upon delivery due to continuous product progressions and improvement. If exactness is required on any item(s), confirm in writing before ordering. In our efforts to provide products with the most up to date engineering and design, we reserve the right to change specifications, dimensions and other product details without notice.

Performance may vary depending upon application.

Products must be installed and operated according to required standards, codes, regulations and safety procedures.

Printer Friendly / Create PDF

Printer Friendly / Create PDF